Contact Us: (205)296-6373

The Next Generation of Air Travel

SE Aeronautics technological improvements will completely change air travel by addressing crucial problems with efficiency and sustainability, COVID flight safety, comfortability, environmental consciousness and operating cost.

Become Part of the Flight Revolution Today

.

70%Fuel Reduction

80%CO2 Reduction

100%Composite

50%Operating Cost Reduction

$7T

Trillion Market

70%Fuel Reduction

80%CO2 Reduction

100%Composite

50%Operating Cost Reduction

$7T

Trillion Market

The Changing Flight Industry

Outdated and inefficient airliners are still being used by the industry, but only because there isn't a sustainable alternative.

Furthermore, in-plane safety has become increasingly important and an aircraft that offers a clean, bacteria and virus free cabin would be revolutionary in and of itself.

.

This is why SE Aeronautics is the future of the flight industry.

We have developed a world-class mid-sized airliner that provides 70% fuel savings at an extremely efficient 500+ Passenger Mile Per Gallon, while also offering a COVID-free ventilation system.

This, along with many other reasons is why SE Aeronautics is ushering in a new era of air travel.

The SE Aeronautics Advantage

Discover how our Intellectual Property is going to completely revolutionize the flight industry.

70% Fuel Savings

Our super-efficiency airliners are designed to optimize fuel consumption by using just a fraction of the fuel compared compared to traditional aircrafts. By switching to SE Aeronautics, airlines can benefit from our incredible 500+ PMPG which could reduce world wide commercial aircraft fuel usage from 100 billion to 30 billion gallons per year.

Our high-lift wings enable short takeoff and landing (STOL) capabilities and super long flights (10,560 miles, London to Sydney)

50% Reduction in Operating Costs

What really captures the attention of airlines is our ability to cut the Block Hour Cost of Operation In half from the industry average. While current airlines operate at an average cost of $4,000 per block hour, adding SE Aeronautics to their fleet will reduce that operating cost to $2,000 per block hour.

How? Apart from the drastic reduction in fuel usage and improvement in lift efficiency, we have also optimized maintenance and financing options with our aircrafts.

80% Reduction in CO2 Emissions

Both airlines and passengers have never been more conscious of the environmental impact of their flights. This means that being able to offer customers a journey that lowers their carbon footprint is not only attractive to airlines, but it is quickly becoming a necessity.

Our airliners are able to reduce harmful CO2 emissions by 80% to 85% as measured by seat kilometer, leading to a more ethical and sustainable trip for passengers.

COVID-Free Ventilation System

The travel industry has been one of the hardest hit by the COVID pandemic, borders closed and local flights were limited due to restrictions. As the world begins to open up once again, keeping passengers secure during flights is a top priority for both airlines and government agencies.

SE Aeronautics has developed a new state of the art ventilation system that reduces passenger exposure by never recirculating air in the cabin. Instead it utilizes a once through jet-fuel heated furnace that keeps the cabin fresh and clean.

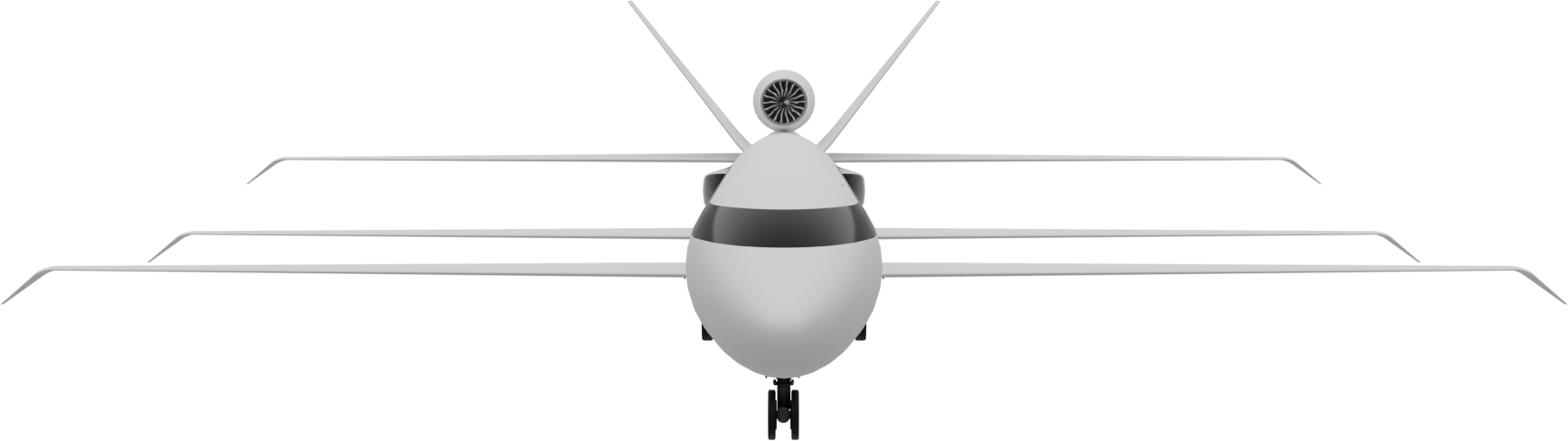

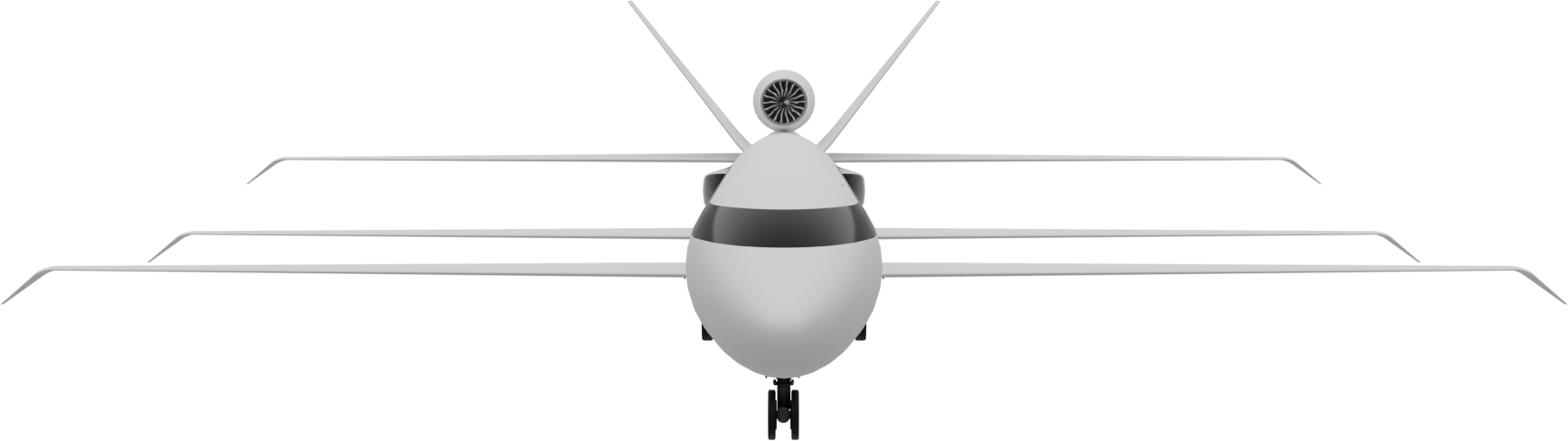

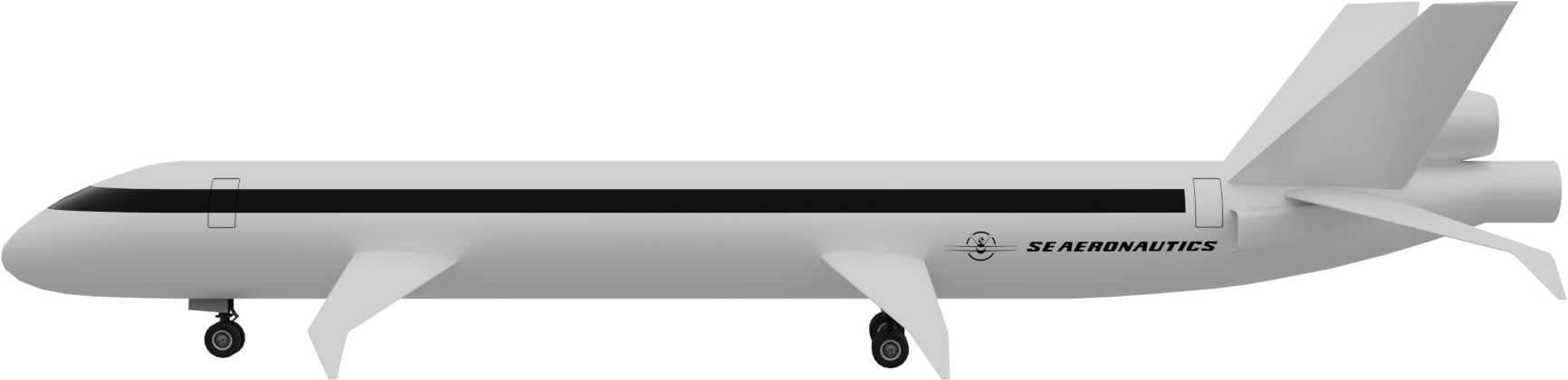

Dynamic Design

Our revolutionary tri-wing design means that lift efficiency doubles in our airliners, while our lightweight and totally streamlined airframe creates a zero-lift drag for seamless takeoffs, super smooth cruising and very slow landings.

Our patent-pending molding technology allows us to completely mold the wings and fuselage in one piece. This makes manufacturing the aircraft not only stronger compared to conventional aircraft, but much safer as well!

Future Advanced Propulsion Systems

SE Aeronautics aircraft design is the absolute most efficient concept ever shown for commercial flight. This means that as alternative propulsion systems such as hydrogen and electric are perfected, our airframe will be the absolute best suited for their integration.

Unmatched Safety and Durability

There are a number of safety features included in SE Aeronautics airliners that are more secure and last longer than existing aircrafts.

First, the lightweight construction of 100% Monocoque Composite Molded materials means that there are no seams or rivets, which are the leading causes of stress cracks on a fuselage.

Our engines are mounted in parallel in the rear of the aircraft. As aircraft engines are typically mounted on wings and can easily ingest birds, SE engines will not have this problem. Additionally, if an engine fails during flight, the aircraft will be much easier to control. The aircraft will also have the ability to takeoff and land at much slower speeds, reducing the risk of hard landings, keeping passengers safer.

Finally, in the case of an emergency landing over water, the SE200 Floats!

The Perfect Opportunity for Growth

One major problem with current aircraft providers is their inability to quickly and effectively produce airliners to meet the high demand of the industry. Both Boeing and Airbus have extreme backlogs, meaning that airlines must wait to receive their aircraft.

The industry projects that there is a need for:

6

Aircrafts

/ Day

2,202

Aircrafts

/ Year

44,040

Aircrafts in

20 Years

SE Aeronautics airline manufacturing methods, once perfected, will be able to produce one plane per week, from start to finish.

By being an efficient and reliable partner that can supply airline companies and governments with the most efficient airliners almost on demand, SE Aeronautics is poised to become the "go-to" airline manufacturer of the future.

Contact Us To Find Out More!

Discover How You Can Be Apart of Revolutionizing Aviation!

IP Portfolio of 7 Key Patent-Pending Points

To date, we have 7 different points that are patent-pending ranging from our tri-wing design, molding methodology, mechanical design, control systems and more.

Trusted Management Team

The SE Aeronautics management team and advisory board bring over 100 years of experience ranging from mechanical engineering, logistics and entrepreneurship, we have a diverse team to lead us in all elements of our company.

TylerMathews

CEO

Entrepreneur, Quilly Inc., Dysautonomia Recovery LLC, Contractor

LloydWeaver

Chief Engineer

Mechanical and Chemical Engineer

Navy buships, Polaroid, Scott Graphics, Southworth Machine Corp, Triple A Sugar, started and sold Septitech

CaptainBill Albin

Member

Rt. Navy Captain, Naval Flight Officer, Mechanical Engineer, MBA

Technical Engineering Leads Over 600 Individuals, Program Management, Systems Engineering & Testing, Acquisitions, Logistics & Strategic Planning

HaroldMathews

VP Marketing & Sales

Pilot 32 Years, Aircraft Business Consultant, Capital Redistribution

A Growing Industry

The growth in air transportation has doubled every 15 years, which would bring air traffic to 16 billion passengers and 400 million tons of cargo for the year 2050. Our ability to meet the growing demand will allow us to capitalize on the market.

The Future of Air Travel Is Here

If you would like to take advantage of this incredible opportunity to become part of the next generation of aircraft, we encourage you to act now and contact us about how you can get involved.

© 2021 Copyright SE Aeronautics. All Rights Reserved.